VEO was responsible for the modernisation of the electrification and automation systems at the Nedre Vinstra hydropower plant, from engineering to commissioning – securing Norway’s power supply and the plant’s reliability for decades to come.

–

Project

Modernisation of Hafslund Kraft’s Nedre Vinstra hydropower plant, part of the Norwegian national grid (annual production 1,308 GWh).

–

What we did

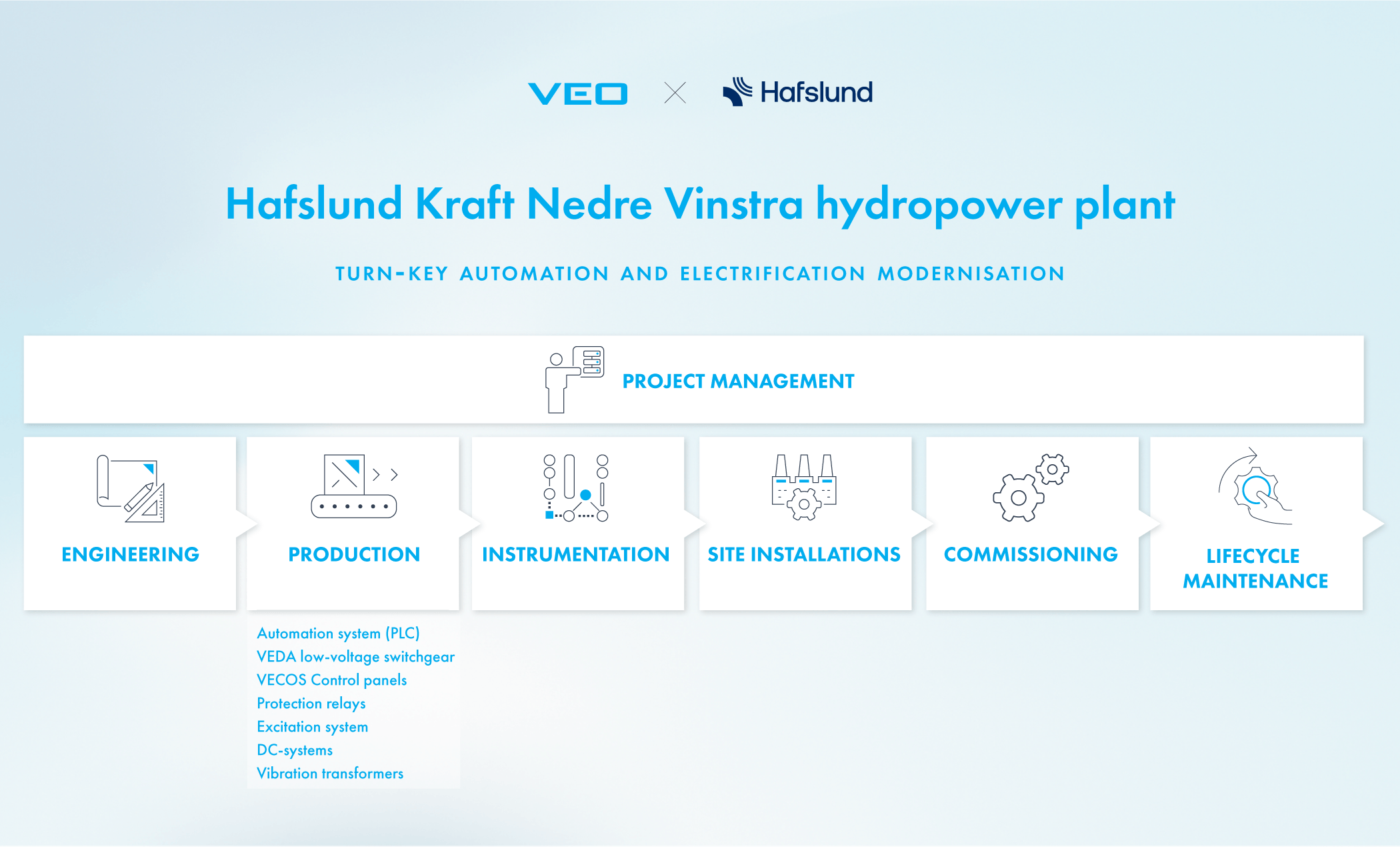

Turnkey upgrade of electrification and automation systems: from engineering and technology manufacturing to installation, commissioning, and project management.

–

Highlights

The five-generator plant was modernised with precise phasing and flexible project management, ensuring uninterrupted power generation and on-time delivery at a facility critical to Norway’s national grid.

“VEO’s expertise ensured stable power supply throughout this extensive modernisation project. Thanks to the project, we can trust that Nedre Vinstra, which is of major importance for the Norwegian electricity supply, will operate reliably in all situations – and for decades to come.”

– Geir Gryttingslien, Head of the Electrical Department, Hafslund Kraft

Norway’s second-largest power producer, Hafslund Kraft, wanted to modernise the Nedre Vinstra hydropower plant located in the municipality of Nord-Fron in Oppland County. The plant is directly connected to the Norwegian national grid and is classified in the highest emergency preparedness class 3. With an annual production of 1,317 GWh, Nedre Vinstra accounts for up to , which made the modernisation exceptionally important for the country’s energy supply.

Precise planning ensured uninterrupted production

Nedre Vinstra is a large underground hydropower plant built into the rock, housing five generators. The modernisation required precise phasing to ensure uninterrupted electricity production throughout the project.

“At VEO, we designed and implemented temporary solutions that allowed part of the generators to continue producing electricity without interruption. This way, a steady power supply was guaranteed during the modernisation,” says Pekka Kurunsaari, Lead Engineer at VEO.

Total project management in VEO’s hands

The modernisation of the plant’s electrification and automation was a comprehensive and demanding project, covering everything from technology engineering and manufacturing to complete cabling, connections, and protection systems. Meeting the strict redundancy requirements of a class 3 plant called for thorough coordination, change management, and close collaboration both within the team and with the customer.

“We took responsibility for the entire project – from engineering and manufacturing to installation, commissioning, and documentation – while keeping the team and stakeholders informed throughout and maintaining control of schedule and budget,” explains Håkan Björkskog, Project Manager at VEO.

“Even though the project schedule changed along the way, at VEO we are used to adapting flexibly. The end result was a modernised plant that is more reliable, better monitored, and fully compliant with the Norwegian authorities’ stringent requirements for high-level redundancy,” Björkskog continues.

A long-term partnership

The collaboration began more than 20 years ago. VEO initially worked with Eidsiva, which later became part of today’s Hafslund through a merger. This long-standing relationship, shared ways of working, and familiarity with VEO’s products created a strong foundation of trust also for the Nedre Vinstra project.

“Unlike many power plants that split operations and maintenance between several providers, Hafslund prefers to work with a single trusted partner. This ensures a unified team and a shared overall understanding of the plant, making collaboration smoother and more efficient. At VEO, we share this mindset – and that is exactly why our collaboration runs so smoothly and will continue in future projects,” Björkskog concludes.

Overview of the turbine hall at the Nedre Vinstra Hydropower Plant, built inside the mountain bedrock

Short History of Nedre Vinstra hydropower plant

Second World War – Final planning of Stor-Vinstra carried out in secrecy

1946 – Vinstra Power Company founded

1953 – First unit commissioned

1958 – Three additional units commissioned (4 × 50 MW total; later two upgraded to 58 MW and 65 MW)

1989 – Expansion with a new 100 MW unit; two separate waterways established

2008 – Modernisation to improve performance

2014 – Further modernisation

2025 – Full electrification and automation modernisation to ensure long-term operational reliability

Want to hear more?

Contact Håkan or Ville for more information: